Harvard scientists use 3D printer to create 4D flower

The latest creation from scientists at Harvard marks a new chapter in biology-inspired engineering. Two teams of scientists worked together to advance 3D microscale printing capabilities with a product that is responsive to time.

Scientists at the Wyss Institute for Biologically Inspired Engineering at Harvard University, and the Harvard John A. Paulson School of Engineering and Applied Sciences, have taken their 3D printing technology up a level – to the fourth dimension.

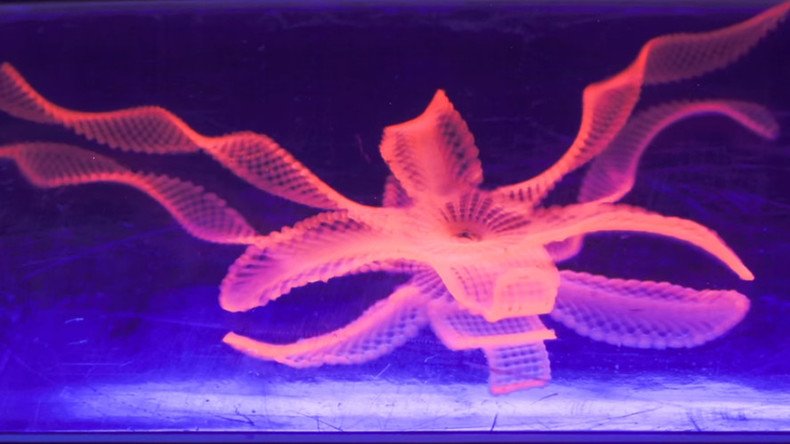

Their biology-inspired creation attempts to mimic natural structures that are able to change form in response to their environment. The Harvard scientists unveiled a “hydrogel composite structure” that resembles an orchid and can change shape when submerged in water.

Novel #4Dprinting method blossoms from botanical inspiration, https://t.co/dvnaVzHIZJ#MaterialsSciencepic.twitter.com/y6ZSpjzu0N

— Wyss Institute (@wyssinstitute) January 25, 2016“This work represents an elegant advance in programmable materials assembly, made possible by a multidisciplinary approach,” senior author of the study Jennifer Lewis said. “We have now gone beyond integrating form and function to create transformable architectures.”

The 4D-printed orchids are programmed with precise and localized swelling, and contain cellulose fibrils, or tiny fibers, from wood. They are meant to function in place of the microstructures that enable plants to change shapes. The outcome is that the make-up of the orchid responds to water – the stimuli – much the same as a typical plant organ such as tendrils, leaves, or flowers might.

As the first layer of the liquid-like hydrogel is laid by the printer, it quickly hardens as the cellulose fibrils are aligned and the composite ink is encoded with directionally-dependent stiffness and swelling. They are then formed into a pattern that results in the orchid’s ability to take intricate shapes. Not only is the orchid then able to move in varied directions, but it can be predicted and controlled.

As the scientists point out in the Harvard Gazette, “The new method opens up new potential applications for 4D printing technology, including smart textiles, soft electronics, biomedical devices, and tissue engineering.”

On podcast DISRUPTIVE, inspiration for the RoboBee and delving into complex systems, https://t.co/zGsk0ErI9Upic.twitter.com/QCEbkQjFYN

— Wyss Institute (@wyssinstitute) January 23, 2016The results of this innovation are dependent on the materials used, and can be tuned to be more conductive of electricity or for more biocompatability. “We can control the curvature both discretely and continuously using our entirely tunable and programmable method,” said Elisabetta Matsumoto, a co-lead author.